The Norseman Difference

Full-service Foam Fabricator

As a leader in the foam fabrication industry, we specialize in creating custom foam solutions for a diverse range of applications.

Our state-of-the-art manufacturing facilities, combined with our extensive knowledge and expertise, enables us to provide high-quality foam products that meet the unique needs of our clients.

From designing and prototyping to production and delivery, our experienced team is committed to delivering innovative, reliable, and cost-effective foam solutions that exceed expectations.

Committed to Excellence

At norseman, we're committed to maintaining our core focus on excellence with every product we bring to life. We strive to create products that are precisely tailored to your specifications.

Custom Design

Our team of foam fabrication experts will work with you to develop or adapt your design, ensuring it's shaped and made ideally for its protective purpose.

Continued Support

As your products evolve, we remain committed to supporting you every step of the way. Whether it's refining your product line through product improvements, revisions, upgrades, or introducing new variations, we're always ready to assist you.

Design-Build Manufacturing

Our team of problem solvers is dedicated to identifying the most suitable solutions that align with your business requirements.

We offer design and build solutions that are tailored to your existing designs or original concepts, incorporating the most innovative and cost-effective manufacturing methods.

Our technical support team can assist you in identifying cost-saving solutions that meet your protective requirements without compromising on quality.

Our in-house designers and technical experts can guide you in material selection and recommend the best manufacturing methodologies to construct your protective solution in a cost-effective manner.

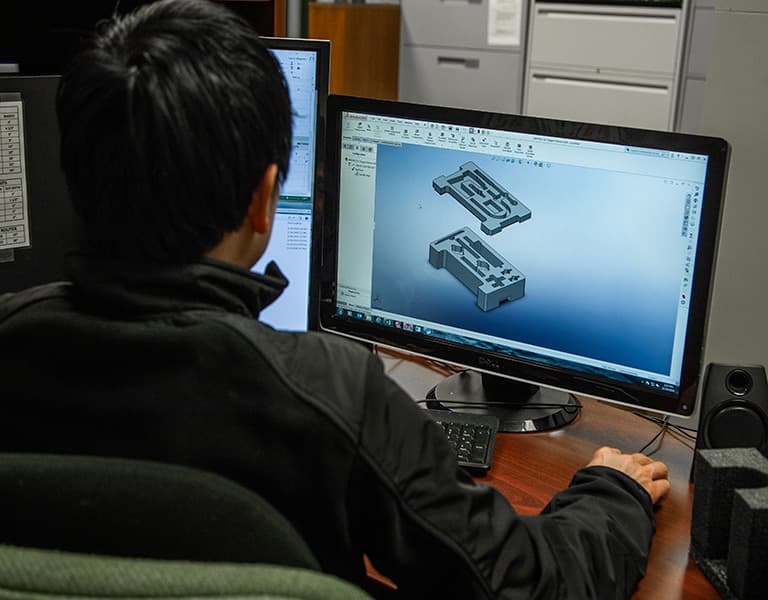

We utilize Solidworks 3D modeling and advanced CAD/CAM equipment to ensure precision in our designs.

We have a vast network of foam and fabric suppliers, both domestic and international, to source the highest quality materials.

Our Process

5P Product Development Process

Produce

Create cost-effective custom protective solutions manufactured from materials we trust.

Prototype

Develop functional prototypes for pre-production validation and verification.

Production

Coast-to-coast manufacturing capabilities, with in-house integrated ERP technology and cross-border logistics with on-time worry-free delivery.

People

We are Fiercely Reliable™, working side by side with suppliers, partners, and customers for over 100 years.

Perform

Reliable protective solutions that help our customers outwork, outperform and overachieve.

Prototyping & Pre-Production

When you have an idea that needs to be designed and tested, and you don't know where to start, our team is able to create solid model renderings and 3D sketches for your innovation.

With our in-house CAD/CAM equipment and expertise, Norseman can produce 3D prototypes to validate and test prior to production.

Our product prototype development team can handle even the most intricate requirements, whether you need proof-of-concept, 3D printing services, molded parts, or functional prototypes.

Trust Norseman to deliver top-notch results that outwork, outperform, and overachieve.

From Suppliers We Trust

WE SELECT MATERIALS THAT PERFORM

Proper material selection for foam solutions requires a clear understanding of the specific application requirements, including properties like density, rigidity, and any unique characteristics, such as fire-resistance (FR) ratings.

Density

Our foams range in density from 1.0 lb./ft. to 12.0 lbs./ft., offering different levels of protection and flexibility based on the application.

Rigidity

The choice of foam depends on the application. Soft, comfortable foams are suitable for sports and leisure, while higher-density foams are better suited for industrial and outdoor recreational products.

UNIQUE PROPERTIES

Foam grades are tailored to specific uses, including hypoallergenic grades for medical settings, marine-grade SOLAS-approved foams, FR-rated options for vertical burn test certificate applications, and Static Dissipative and Conductive grades for sensitive components.

SUSTAINABILITY

Norseman believes in successful, sustainable business practices as we strive to reduce waste to landfills with low-density foams.

A CENTURY OF MANUFACTURING EXCELLENCE

With over 100 years of manufacturing expertise, Norseman has the knowledge and skill to deliver successful results.

And thanks to an established worldwide network of foam suppliers, we have access to virtually any foam specification you need to protect your products.

Norseman’s QMS at our Langley, BC facility is certified as being in conformity with ISO 9001:2015 and ISO 13485:2016 by Intertek.

FAQS

FREQUENTLY ASKED QUESTIONS

VERSATILE FABRICATION

INDUSTRIES WE SERVE

Norseman can tailor foam fabrication capabilities to suit any industry, providing bespoke solutions designed precisely to your specifications.