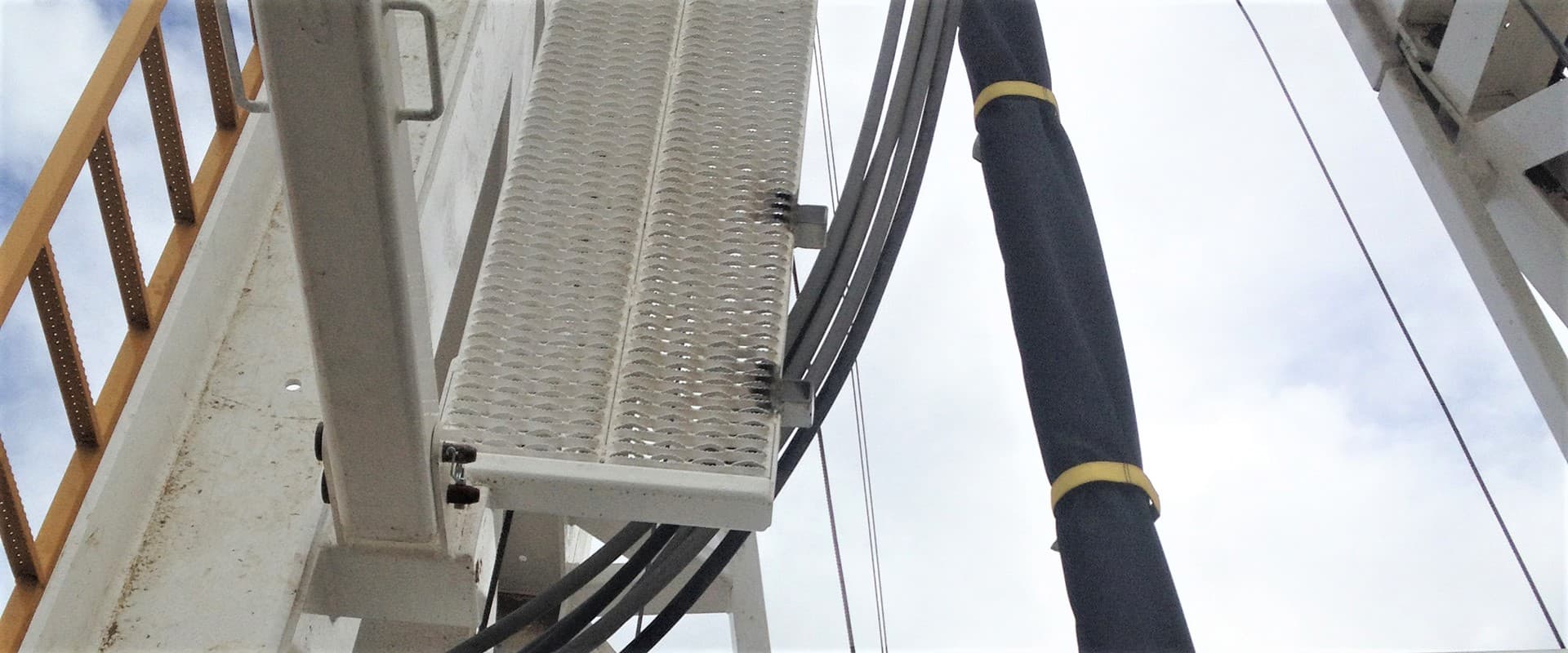

MANAGE CABLES. PREVENT DAMAGE. AVOID DOWNTIME.

Keep service loops bound together, preventing hang-ups in the mast or damage from harsh weather conditions. Organize power cables to keep them off the ground, protecting them from equipment and weather, while reducing stress on cables ... which all help lower maintenance costs.

Constructed with reinforced ballistic nylon fabric with a high-performance hook and loop fastener.

They can be easily removed for inspection and maintenance of the service loop without removing the cover, reducing rig downtime.

Features

Constructed with reinforced ballistic nylon (1680 denier) that is heavy-duty and cut-resistant

Fire-resistant (FR) fabric tested to Fed. Std.191A, Method 5903, and NFPA 701, Small Scale Test.

Turned and sewn edges to prevent nylon fray

High-performance hook-and-loop fasteners for longevity and improved adhesion

2” tie-down webbing straps approximately every 4’ provide a secure closure system

Yellow tie-down webbing rated at 10,000 lb break strength.

Three 2” welded D-ring attachment points on each end secured and reinforced with webbing.

Locking carabiners on each end help to hold the cover in place securely

Custom sizes and configurations are available

BENEFITS

GEAR POINTS

Avoid repair costs and downtime associated with service loop damage.

Protect

Prevent cables from snagging or becoming entangled in the mast.

Withstand

Fabricated with heavy-duty reinforced ballistic nylon and a high-performance hook-and-loop fastener.

Resist

Cut-resistant with turned-and-sewn edges to prevent nylon fray.

Fit

In-stock, ready-to-order products and custom configurations are also available.

Perform

Quick and easy to install with a secure closure system that can easily be removed to inspect and maintain cables.